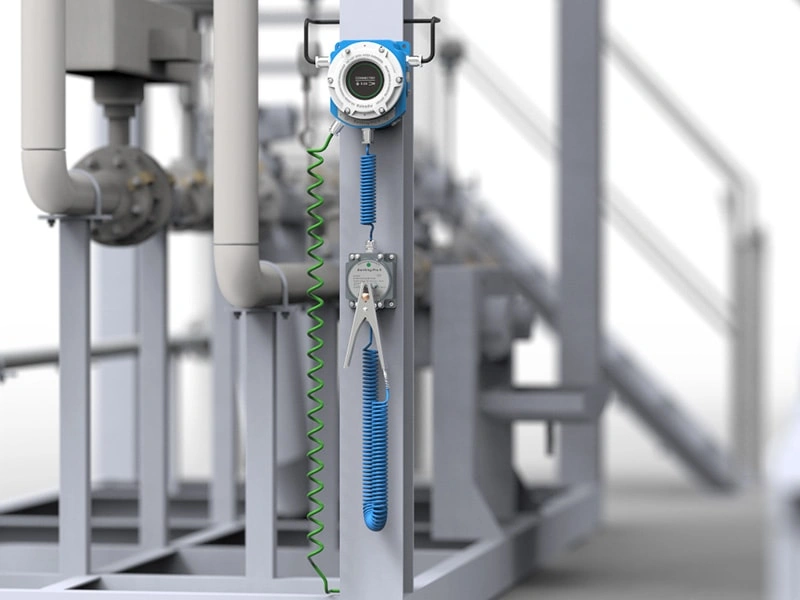

Earthing Pro GE is a true earth verification system designed to prevent ignition risks caused by static electricity during tanker loading and unloading operations.

Unlike conventional grounding monitors that only detect metal contact, Earthing Pro GE actively verifies a genuine low-resistance connection to true earth before enabling operation.

In hazardous area loading operations, a visible metal-to-metal connection does not necessarily mean a true earth is present.

Paint coatings, corrosion, grease, insulated components or vehicle construction can create a false grounding path. In such cases, static charge may remain undetected, significantly increasing the risk of ignition.

True earth verification is therefore essential for safe tanker loading operations.

Continuous grounding monitoring

Visual and audible grounding status indication

Integrated self-diagnostic system

Designed for hazardous area applications

|

Ground Resistance Threshold |

≤ 10 Ω (typical) |

|

Response Time |

< 1 second |

|

Outputs |

On-off signal,10A 250VAC/5A 30VDC |

|

Supply Voltage |

85~250 V / 24~48 V |

|

Operating Temperature |

-20 °C to +60 °C |

Tank truck loading racks

Road tanker unloading stations

Flammable liquid transfer operations

Alarms indicate conditions such as grounding not verified, open circuit, or abnormal status to provide immediate on-site awareness. Exact behavior depends on the configured interlock logic.

Use the permissive relay output to wire into the permissive/shutdown logic of pumps, valves, or ESD circuits, in accordance with the site’s control philosophy and interlock design.

It verifies grounding status and provides a permissive relay output for safety interlocking. This turns grounding confirmation into a verifiable control point before loading, filling, or transfer operations.

Yes. It is designed for hazardous-area applications and is certified (ATEX / China Ex / CCC) within the scope defined by the certificates.